Since the early days of European style building construction in Australia and New Zealand, timber floors have been a common feature in houses and public buildings, where conventional construction methods used timber flooring extensively as an integral part of the building’s structure.

Timber floors provide the basic walking surface in the building and nowadays they provide an attractive feature in a home or entertainment venue when they are polished to highlight the characteristics of the timber.

The attractive finish of any polished timber floor can however be diminished in a number of ways including:

- Heavy foot traffic in only some areas of a floor, resulting in a “worn pathway”

- Careless movement of furniture leaving drag marks

- Chair legs which provide a very small load bearing area

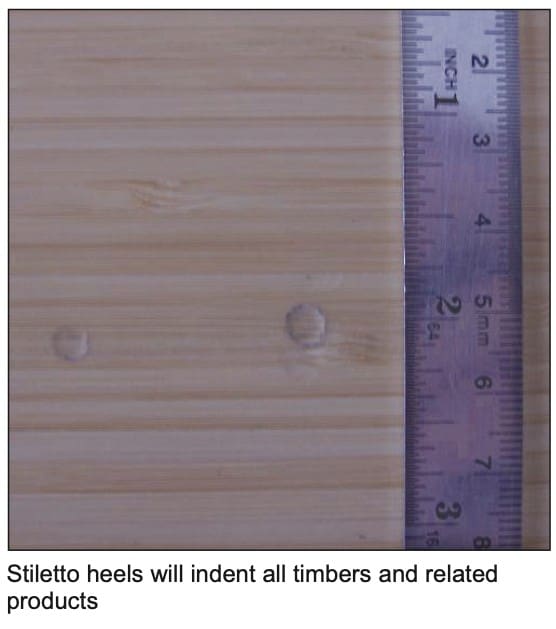

- Stiletto heels which can cause a great deal of damage to all types of flooring, even very hard timber species

In most cases, appearance is the main consideration on which the selection of flooring species is made. Appearance is influenced by colour, amount of feature, general character, width of the boards, size of the room, direction of lay and the finish applied.

While many of our Australian hardwoods are rated as ‘Very Hard’ or ‘Hard’, there are many ‘Moderately Hard’ Australian species that provide an attractive and durable feature floor. Therefore, for most household applications, a species with a hardness rating of ‘Moderately Hard’ will be appropriate.

For some heavy use applications greater consideration should be given to selecting a species of appropriate hardness to suit the application. The selection of a hard timber species can provide improved resistance to indentation and abrasion, but it must be considered that most timbers are highly suitable as a domestic floor and aspects other than hardness will often govern the choice.

When choosing a ‘Soft’ species, which is often done to meet the specific character of a dwelling, then additional care is necessary to prevent indentations such as the removal of certain foot ware. In other instances, the indentations are seen as part of the character of the dwelling and not of concern to the owner.

One further point of importance is that finishes do not improve the hardness of the floor surface.

Janka Hardness Testing

The hardness of timber is not directly related to how hard or easy the timber is to work with various tools but is a measure of the resistance of the wood to indentation. The hardness figures most commonly used are those obtained from the Janka test.

The Janka test is a standard test which measures the force (kN) required to press a steel ball of 11.18 mm diameter into the test specimen until the ball has penetrated to half its diameter.

There are Janka hardness figures available for many common species. The figures are for side grain and represent an average for tangential and radial surfaces. As some of the figures are based on only a small sampling, they are not appropriate for making fine distinctions between species. There are 2 sets of figures, one for “green” or freshly felled timber and one for seasoned or dried timber as you would find in timber flooring and tested with a timber moisture content of 12%.

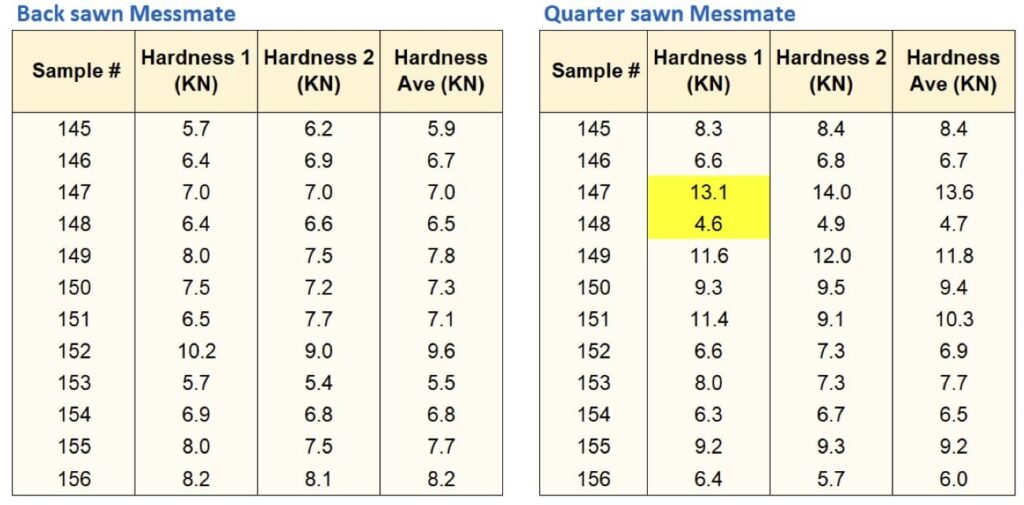

In some species the hardness of younger growth material can also be much lower than mature timber of the same species, but this varies from species to species. So, it is important to realise that the hardness variance within a species is very variable and this is illustrated by the results in the table below. Ten to twenty tests on a backsawn face and similar on a quartersawn face are undertaken and, as indicated above, the results are averaged.

For Messmate, one piece a hardness of 4.6kN and another 13.1kN. The average for this test is 7.2kN backsawn and 8.4kN quartersawn so the figure given is 7.8kN for Messmate for this test. This compares with a published figure of 7.1kN.

So, where you see a published figure or 7.8kN the actual hardness values from the testing could be between 4.6kN and 14.0kN. It is therefore not right to suggest or imply that this timber is harder than another that may have a hardness value of say 7.1kN.

Because the figures are not appropriate for making fine distinctions between species, species are generally rated as:

- Soft

- Moderately Hard

- Hard

- Very Hard

The table below provides some examples of species hardness ratings.

Hardness of engineered and other timber flooring products

In addition to solid timber flooring products there is engineered flooring, laminate flooring and bamboo.

Engineered flooring generally has a solid timber face veneer or lamella from 1mm to 6mm in thickness on the upper exposed surface. It is sold as this timber species and the hardness of the product relates to that species. As such the hardness categories in the table above apply to the species but not the product. Where the face veneer of lamella is much thinner the core timber will significantly influence the hardness.

Bamboo flooring is available as a laminated product (vertical and horizontal) as well as the strand woven product. In terms of our categories above the laminated products would be regarded as hard and the strand woven product as very hard.

Laminated flooring is constructed with a melamine coating over a hardboard core. With these products there is usually an ‘Abrasion Class’ associated with them which relates to their overall wearability and suitability from domestic through to commercial applications.